BASF unveils innovative and sustainable total solution photovoltaic frame co-created with Worldlight at CHINAPLAS 2024

BASF unveils innovative and sustainable total solution photovoltaic frame co-created with Worldlight at CHINAPLAS 2024

- Aluminum replaced with a total solution of polyurethanes composite and water-borne coating solution

- 85% reduction in product carbon footprint vs aluminum frames

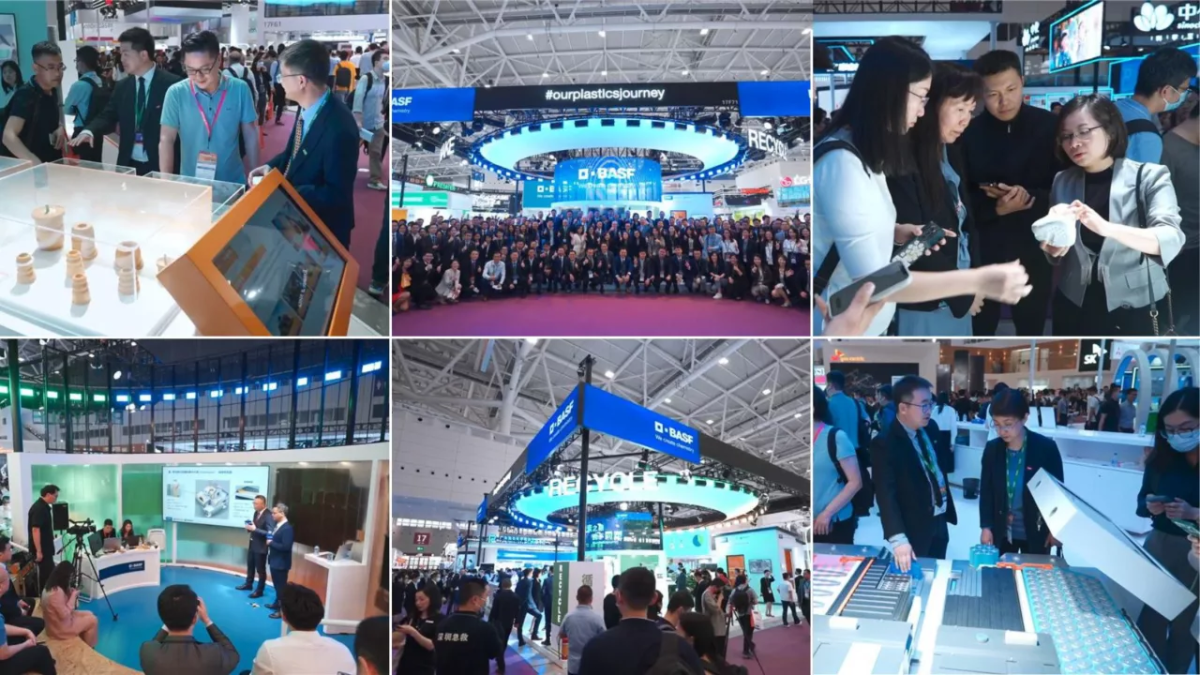

- BASF at CHINAPLAS 2024: Hall 7.2, Booth C42, National Convention & Exhibition Center, Shanghai, China

At CHINAPLAS 2024, BASF will unveil a total solution photovoltaic (PV) frame, co-created with Jiangsu Worldlight New Material Co., Ltd (Worldlight), a global manufacturer of PV composite frames. The PV frame, made with an industry-leading total solution that combines polyurethanes (PU) composite with a water-borne coating solution, results in an 85% reduction in product carbon footprint (PCF) vs aluminum frames. The water-borne coating solution further reduces the emission of volatile organic compounds (VOCs) by more than 90%.

PU composite is more energy-efficient to produce than aluminum. When combined with the water-borne solution, the total solution is also lighter weight and possesses superior insulation. Hence it is also more energy-efficient in use. Additionally, the exceptional adhesion properties of the waterborne coating solution to PU composites significantly enhance weathering resistance, which translates to higher durability and a longer life span of the PV frame.

"Worldlight has created three main applications for different scenarios: offshore PV modules, large-scale terrestrial PV modules as well as industrial and commercial rooftop PV modules. BASF's total solution enables us to meet strict standards and overcome challenges from diverse environmental conditions and design specifications," said Mr. Liang Zhao, CEO, Worldlight.

PU composite, made of glass fiber-reinforced polyurethanes, has been widely used in automotive, bridge construction, and aerospace industries. Compared to aluminum, PU composite with coating provides superior cost performance and mechanical properties, including resistance to abrasion, acids, alkalis, and UV radiation.

"BASF has consistently demonstrated how we support our partners to develop innovative material solutions that meet the demanding needs of the industry as well as evolving trends and regulations. Through our collaborative efforts with Worldlight, a market leader in composite PV frames, we will further explore the potential of composite PU materials with waterborne coatings as a total solution for this promising industry," said Silvia Mok, Vice President, Business Management Polyurethanes Systems, Performance Materials Asia Pacific, BASF.

BASF is accelerating its plastics journey towards a more sustainable future! At CHINAPLAS 2024, BASF will showcase its latest innovations, competencies, and developments - particularly in the areas of sustainability and co-creation. Join us at CHINAPLAS 2024 and let us walk you through the MAKE-USE-RECYCLE phases in our plastics journey.

ติดต่อเราได้ที่ facebook.com/newswit